Drag Chain Cables: The Complete Guide to High-Flex Industrial Cables | YUEDAO Manufacturing

What Are Drag Chain Cables?

Drag chain cables (also known as tow or energy chain cables) are ultra-flexible cables designed for high-frequency reciprocating motion, capable of withstanding millions of bends without wear or fracture. With the global industrial automation market growing at an 8.5% CAGR through 2030 (Grand View Research), demand for drag chain cables as critical components continues to surge.

5 Core Advantages of Yuado Drag Chain Cables

-

Extreme Flexibility: Endures over 5 million bending cycles (tested to ISO 11801 standards).

-

Tensile & Abrasion Resistance: Central tensile reinforcement + armored inner jacket increases tensile strength by 40%.

-

All-Environment Protection: Resists oil, water, and UV radiation, operating from -40°C to +105°C.

-

EMI Immunity: >85% tinned copper shielding exceeds industrial EMC standards.

-

Customization: Supports bespoke configurations in conductor count, length, and jacket materials (PVC/TPE).

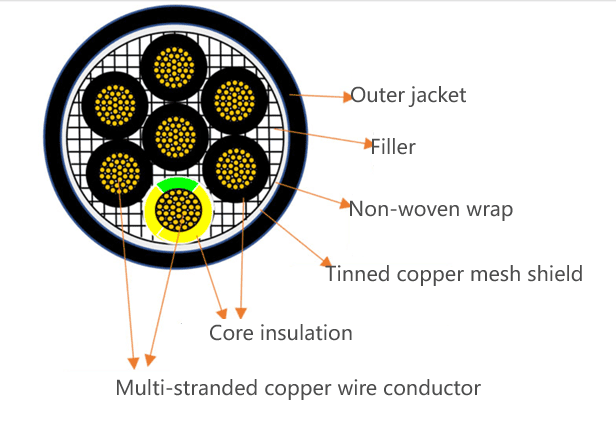

7 Core Technologies Behind YueDao Drag Chain Cables

| Technology | Innovation |

|---|---|

Tensile Structure |

High-density central/bilateral fillers ensure stability (tensile strength ≥200N/mm²). |

Conductor Design |

Ultra-fine 0.1mm oxygen-free copper strands, diameter tolerance ±0.004mm, resistivity ≤0.0175Ω·mm²/m. |

| Insulation | High-pressure molded PVC/TPE insulation, withstands >3kV voltage, zero interlayer adhesion. |

Stranding |

Optimal lay length around tensile core, minimum bending radius 7.5×cable diameter. |

Inner Jacket |

Armored, extruded inner jacket replaces loose fillers, improving torsion resistance by 30%. |

Shielding |

>85% tinned copper braid with ≤30°编织角度, blocking 99% EMI. |

| Outer Jacket | NBR-PVC hybrid material, abrasion resistance >5000 cycles (DIN 53516), IP67 oil resistance. |

Key Applications for Drag Chain Cables

-

Industrial Robots: Wiring for 6-axis arms, enduring 10+ bends per minute.

-

CNC Machines: Powering moving parts (tool changers, rails) in oil-heavy environments.

-

Automated Production Lines: AGVs (Automated Guided Vehicles), conveyor belts (lifespan ≥5 years).

-

Warehouse Logistics: High-frequency cable management for stackers and sorting systems.

-

Special Equipment: Firefighting platforms, port cranes with anti-sway cabling.

Yuado Drag Chain Cable Series

| Model | Structure | Applications | |

|---|---|---|---|

| TRVV | PVC insulation + PVC jacket, unshielded |

General equipment (≤380V power). |

|

| TRVVP | PVC insulation + shielded + PVC jacket |

Precision sensors (EMI resistance). |

|

TRVVSP |

Twisted pair + overall shielding |

Industrial Ethernet (Profinet/EtherCAT) |

|

| RVVYP | Oil-resistant jacket (hydraulic/lubricant) | Automotive, injection molding (high-temperature oil environments). |

How to Select Drag Chain Cables

-

Motion Parameters:

-

Bending radius ≥7.5×cable diameter.

-

Acceleration ≤50m/s².

-

-

Environmental Needs:

-

Choose RVVYP for oil/grease exposure.

-

UV-resistant jackets for outdoor use.

-

-

Electrical Requirements:

-

TRVVSP for signal integrity.

-

≥25mm² cross-section for high-current loads.

-

Certifications & Performance Data

-

Compliant with ISO 11801, UL AWM, and RoHS standards.

-

Tested lifespan: Insulation resistance >100MΩ after 10 million bends (IEC 60227).

-

Case Study: An automotive welding line using TRVVP reduced failures by 60%, saving $17k annually.

FAQ Section :

Q: How do drag chain cables differ from standard cables?

A: Drag chain cables use 7 core technologies (e.g., fine-strand conductors, armored jackets) to survive millions of bends vs. standard cables (≤50k cycles).

Q: How to calculate minimum bending radius?

A: Formula: Bending radius = Cable diameter × 7.5. Example: 10mm cable requires ≥75mm radius.

Q: Temperature limits for drag chain cables?

A: Standard: -40°C to +105°C. High-temp versions (silicone jackets) available up to +150°C.

Leave a Reply

- HYA 50×2×0.4 Communication Cable: Reliable Solution for Guangzhou Surveillance Systems

- Why Does Your EV Stop Charging Suddenly? Let’s Troubleshoot!

- Yuedao Intelligent Empowers Guangzhou Metro to Set World Record for Fastest Subway Speed

- Become Our Local Partner - Expand Your Market with High-Quality Cables & Wires